Introduction

The major development goal of Livermore Software Technology (LST) is to provide within LS-DYNA capabilities to seamlessly solve problems that require

One Code Strategy

- "MULTI-PHYSICS"

- "MULTIPLE STAGES"

- "MULTI-PROCESSING"

LST develops sophisticated tools for modeling and simulating the large deformation behavior of structures. In addition to LS-DYNA the tools LS-PrePost for pre- and post-processing, and LS-OPT for optimization are developed by LST.

Its fully automated contact analysis capabilities and error-checking features have enabled users worldwide to solve successfully many complex crash and forming problems. LS-DYNA simulation results have been consistently correlated with experimental data at various customer sites. These extensive tests give the user high confidence in using the program as an accurate simulation tool. Before each release, the program is subjected to rigorous quality assurance testing which consists of over 300 test problems. You find the most important functions of LS-DYNA in the menu option Features.

Main Application Areas

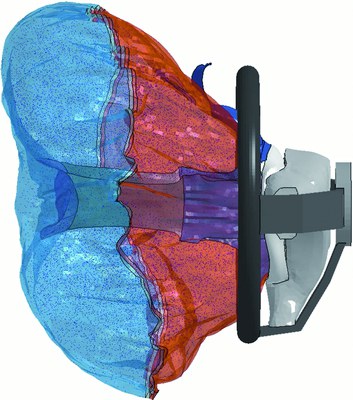

- Crash- and pedestrian safety in automotive

- Dummy, airbag, barrier

- Seat belt, retractors

- Automotive part manufacturing

- Car body, seats, roofs, doors

- Hoods, fender, bumpers,…

- Simulation of manufacturing process

- Deep drawing (incl. gravity sim. and springback)

- Rolling, pressing, forging, casting, spinning

- Superplastic forming, hydroforming, hemming

- Multi-stage processes, metal cutting

- Roller hemming, profile rolling

- Glass forming

- Biomedical applications

- Stability/ failure investigations

- Cranes

- Seat tracks

- Bounce and drop tests

- Mobile phone

- Consumer products

- Tools

- Nuclear vessels

- Earthquake engineering

- Aerospace

- Bird strike

- Jet engine blade containment

- Material behaviour of composites

- Blast loading

- Spot-welded, riveted and bolted structures

- Fluid dynamic

- Fluid-structure interaction

- Shipping containers

- Eigenvalue analysis

- Penetration problems

- Plastics, mold and blow forming

Further Informations

You are welcome to order a free test license. With the help of the manuals, examples and the LS-DYNA support you can learn quickly the handling with LS-DYNA. Additionally, DYNAmore offers a wide range "LS-DYNA seminars".