Material Competence Center

LS-DYNA is regarded as one of the world's most powerful software tools for structural simulation - both in terms of possible model sizes, achievable speed-up in parallelization for cluster systems, and the availability of complex and specialized material models. This offered functionality is extended towards many application areas when coupled systems, e.g. thermal, electromagnetic, or fluid dynamic problems, play a significant role.

Access to high-quality material data down to the failure and fracture range is critical for the predictive capability of corresponding simulation calculations, enabling the identification of all necessary model parameters and ultimately the successful calibration of material models. To this end, DYNAmore has in recent years advanced the data acquisition from experiments and the efficient parameterization of material models and recently bundled the competences of our employees with the move to new premises and the creation of a Material Competence Center in Leinfelden-Echterdingen at one location.

Calibrated material cards and optimal modeling techniques

- Metallic materials up to failure prediction (GISSMO, eGISSMO, DIEM, etc.)

- Polymers and composites (non-reinforced, short fiber-reinforced, continuous fiber-reinforced)

- Elastomers

- Glass (float, thermally or chemically tempered) and ceramic materials

- Connection technology (punctiform, linear, flat)

Furthermore we see our competence in the calibrated transfer of simulation process data from component manufacturing (injection moulding, extrusion, forming, heat treatment, hot forming, casting, solid forming, draping, etc.) into downstream component or full scale simulations (crash, impact, stiffness, etc.). For this purpose we regularly use our process mapper ENVYO, a DYNAmore in-house development.

Experiments

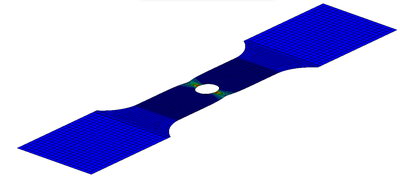

The mechanical properties of many materials that are required for simulation are often unknown. Defining these precisely is typically very expensive and often involves a considerable wait. In contrast, the experiments we select in accordance with the specific requirements of the client provide a quick and reliable basis for generating predictive material cards for polymers, metals and composite materials.

Our services

- Static, dynamic, and cyclic testing

- Tensile, compression, puncture, and bending testing

- Component testing

- Sample conditioning

- Sample processing and collection from components, sheets and panels

- Optical 3D strain measurement and detailed local distortion evaluation

Your benefits

- Testing and adjustment from a single source

- Time and cost efficient

- LS-DYNA developer team is always nearby

Material models and calibration

The quality of the material cards has a significant influence on predictability in numerical calculations. In addition to advanced testing processes, our customers benefit from our engineers’ many years of experience in the area of numerical description of mechanical material behavior.

Our characterization spectrum includes

Deformation behavior

- Viscoelastic and viscoplastic

- Isotropic or anisotropic

- Tension–compression asymmetryDeformation behavior:

- Viscoelastic and viscoplastic

- Isotropic or anisotropic

- Tension–compression asymmetry

Damage and failure modeling

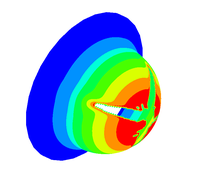

- GISSMO (Generalized Incremental Stress State dependent damage Model)

- DIEM (Damage Initiation and Evolution Model)

- eGISSMO (Mat Add Generalized Damage)

- Damage development under cyclic load

We are sure that we can also offer an economically interesting solution for your material challenge. Please contact us!