KI-Last

One of the most important global goals is to significantly slow down or even stop global warming by reducing greenhouse gas emissions. In the automotive industry, the subject of "lightweight construction" plays a central role in significantly improving the carbon footprint of motor vehicles.

A solution to this challenge is being investigated as part of the new BMWi-funded project KI-LaSt. The idea is to support the design process for ultra-light, additive manufactured lightweight crash-relevant vehicle components using artificial intelligence (AI).

When it comes to lightweight construction, vehicles are designed to be as weight-optimised as possible. In addition to new production technologies, such as additive manufacturing (3D printing), the vehicle industry is relying on the increased use of modern virtual optimisation processes.

Vehicles are developed with the help of mathematical calculation methods, such as finite element structure simulation, and are successively optimised regarding lightweight construction. The structure simulation is therefore a key element of the efficient automotive development process. Without this step, it is no longer possible to develop a new vehicle for series production today.

However, this also means that a) every new lightweight component must go through appropriate simulation phases during its development, and b) the simulation methods must be predictive.

The associated simulation methods must be so sophisticated that they can map the real component behaviour in the test as precisely as possible. To be successful, the simulation departments must develop validated and efficient simulation methods in advance. These then make it possible to optimise vehicles in terms of lightweight construction and at the same time to design them according to the highest crash level.

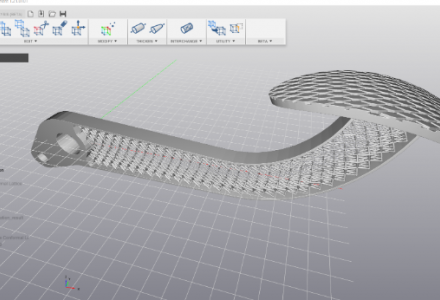

New manufacturing processes, such as additive manufacturing, enable highly complex and ultra-light component geometries using innovative lightweight materials, such as those used for the first time in the context of KI-LaSt. The status is that the structural behaviour of such vehicle components cannot be mapped efficiently and with sufficient accuracy using current simulation methods, which means that these new technologies are hesitant to enter the vehicle.

Another challenge in the design of additively manufactured vehicle parts is the availability of selectable parameters for designing the 3D lattice structures. The proper choice of these parameters may influence the mechanical behaviour of the crash-loaded components significantly. However, it is difficult for designers to grasp these relationships, resulting in time-consuming and resource-intensive design iterations, which are not acceptable for the industrial development process. Furthermore, current metallic materials that are used in additive manufacturing are not sufficiently ductile for many crash-relevant vehicle applications.

This is precisely the challenge which the project KI-LaSt is addressing: With AI, these parameters will be selected automatically to identify suitable structures in a more targeted and resource-efficient manner, so that the development process can be significantly accelerated at this point. Furthermore, a CAE process chain is to be set up that holistically maps the virtual, AI-based development process for the corresponding components. In addition, the use of additive manufactured components in crash-relevant areas of the vehicle should be made possible by new, ductile materials.

The project is funded within the call "Artificial intelligence as a key technology for the vehicle of the future" from the Federal Ministry for Economic Affairs and Energy (BMWi) with € 2.19 million under the funding number 19I21036 and supervised by TÜV Rheinland.

Under the direction of Ford-Werke GmbH, the companies AM Metals GmbH, DYNAmore GmbH, BETA CAE Systems International AG, EOS GmbH and RWTH Aachen with the Institute for Automotive Engineering (ika), the Chair of Software Engineering (SE), the Institute of Structural Mechanics and Lightweight Design (SLA), and with the Department of Computer Science at the Eberhard Karls University of Tübingen (UT) will collaborate closely over the next 3 years. The company nTopology GmbH is also involved in the project, for example to generate 3D lattice structures for vehicle components with their software ntop.